CAPABILITIES & SERVICES

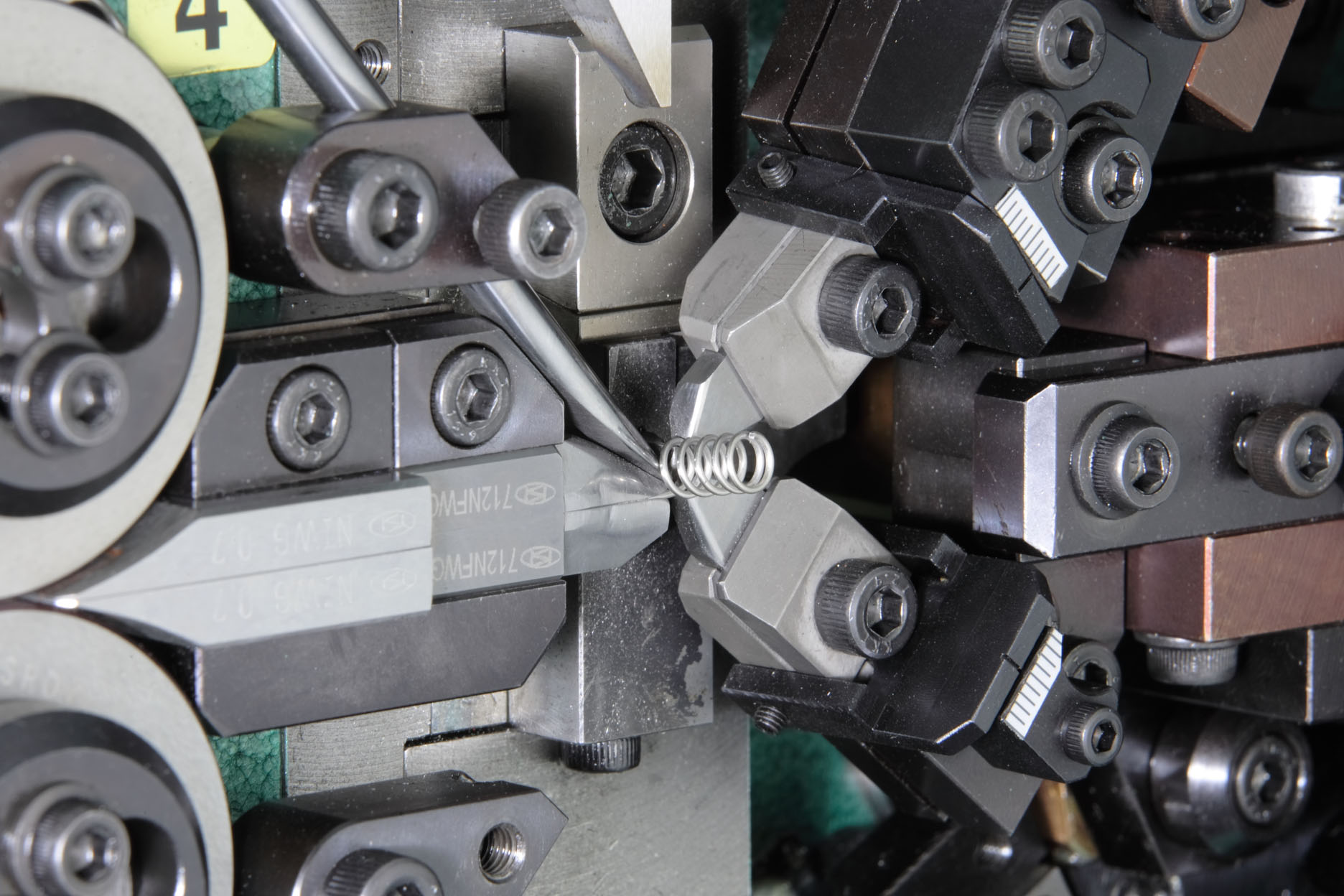

Custom Spring & Wire Form Capabilities

Materials - commonly used

- Brass

- Carbon Steel

- Copper

- Hastelloy

- Inconel

- Music

- Stainless Steel

- Steel

- Can provide any material

Spring Forms

- Custom Manufacturing

- Compression Springs

- Extension Springs

- Torsion & Double Torsion Springs

- Flat Springs

Direction of Helix

Spring & Wire Form Wire Range

Fabrication Process

- Bending

- CNC (Computer Numeric Controlled Machining)

- Cold Forming

- Cutting

- Straightening

- Flattening

- Fourslide

- Looping

- Straightening

Additional Services Available

- Rapid "turn around"

- Expediting

- Warehousing / KANBAN

- Special Packaging

Value Added In-House Service

- shot peening

- grinding

- heat treating

- vibratory tumbling

- corrosion resistant applications

- In line ovens for stress relieving

- Set removal

Strategic Partnership Outside Process:

- Dry Film Lubricants

- Electropolished

- Pasivation

- Tin, Nickel, Gold Plated

- Black Oxide, E-coat, Zinc Plated

- Powder Coated

- Any other customer requirements

Custom Manufacturing Equipment List

- Multi-Axis CNC Wire Formers

- CNC Spring Coilers

- Mechanical Coilers

- Fourslide Machines

- Presses

Production Volume

- Specialty Production Shop

- Large Run

- Large Scale Production Volume Run

- Long Run

- Low Volume

- Prototype

- Small Run

- High Volume

Typical Lead Times

- 4 weeks - Standard Orders

- Customer Requests with Contracts

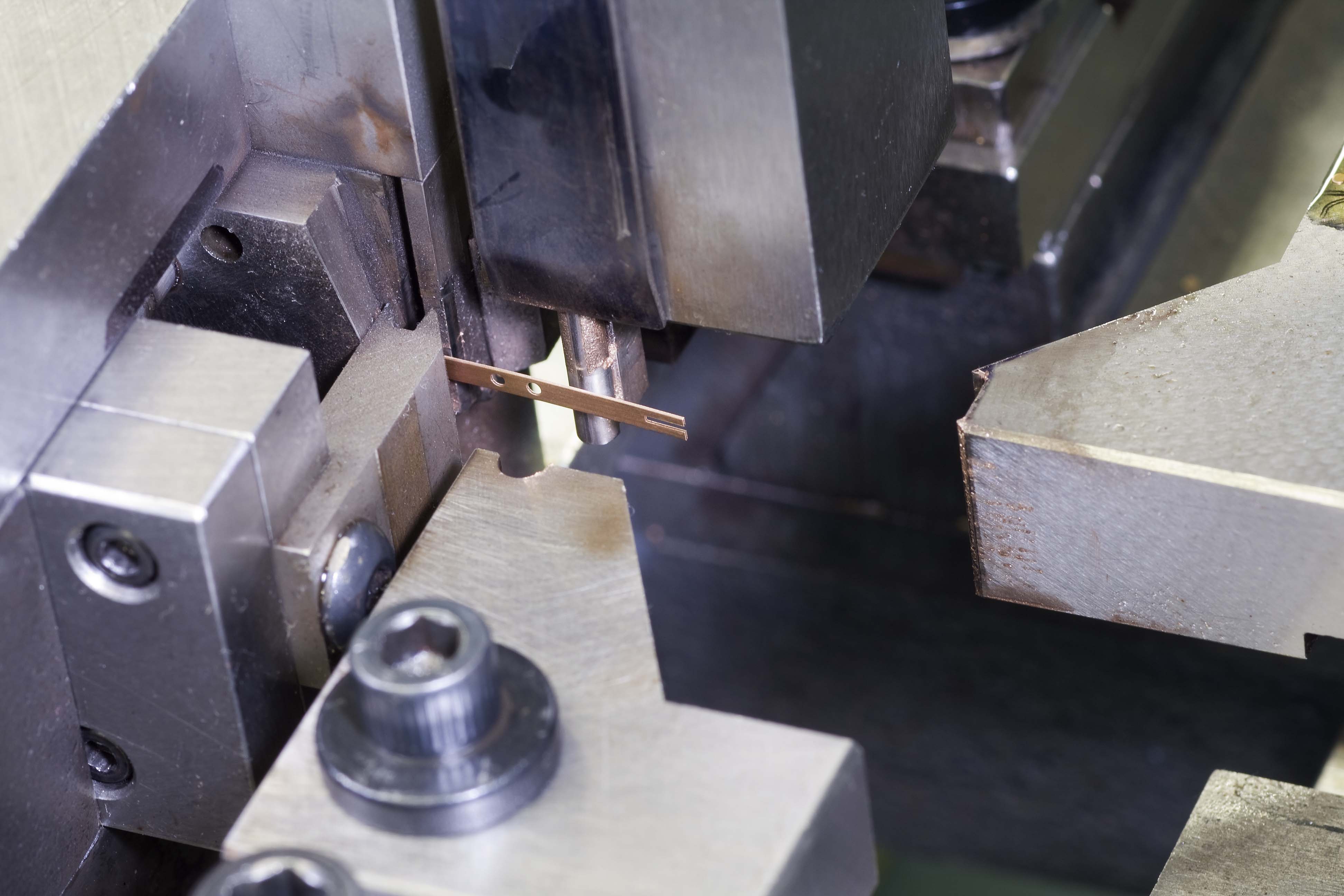

Custom Fourslide Capabilities

Materials - commonly used

- Aluminum

- Brass

- Phosphor Bronze

- Copper

- Beryllium Copper

- Nickel

- Nickel Silver

- Cold Rolled Steel

- High Carbon Steel

- Stainless Steel

- Inconel

- Can provide any material

General Capabilities

- Custom Manufacturing

- clips

- flat springs

- flat stock

- wire forms

- small stampings

- fasteners

Press Rating

Feed Length

Stock Width

Material Thickness

- .004" - .093” Material Thickness

Wire Diameter

Additional Services Available

- Rapid "turn around"

- Expediting

- Warehousing / KANBAN

- Special Packaging

Value Added In-House Services:

- shot peening

- grinding

- heat treating

- vibratory tumbling

- corrosion resistant applications

- In line ovens for stress relieving

- Set removal

- *Secondary Operations such as drilling, tapping, chamfering, notching, piercing, forming, welding, wire stripping*

Strategic Partnership Outside Processing:

- Nickel

- Electroless Nickel

- Gold

- Silver

- Chrome

- Chromate

- Tin

- Zinc

- Phosphate

- Passivation

- Color Coding

- Black Oxide

- Teflon

- Powder Coat

- Epoxy/Plastic

Production Volume

- Specialty Production Shop

- Large Run

- Large Scale Production Volume Run

- Long Run

- Low Volume

- Prototype

- Small Run

Typical Lead Times

- 4 weeks - Standard Orders

- Customer Requests with Contracts

In-house Tool and Die Capabilities

General Capabilities

(Standard Lead Time - 8 weeks)

- Contract Manufacturing

- Prototypes

Production Method

- Coining

- Compound Dies

- Deep Draw

- Forming

- Fully Sheared stamp edge

- MIG Welding

- Progressive Die Presses

- Blank Dies

- Form Dies

- Tapping